Project Details

Program

Chemical Engineering

Field of Study

separation processes ; transport phenomena ; modelling

Division

Physical Sciences and Engineering

Faculty Lab Link

Center Affiliation

Advanced Membranes and Porous Materials Center

Project Description

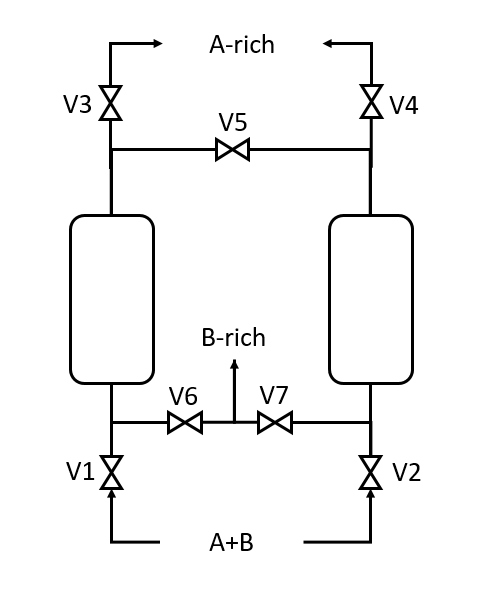

Adsorption processes are emerging separation technologies that have the potential to cut energy consumption in many different separations vital to society. Differently from other separation technologies, adsorption processes are transient processes where the operation of a bundle of columns is synchronized to operate in an efficient manner.

Modelling the performance of adsorption processes involve the utilization of advanced modelling tools that will be learnt in this project. The student will learn how to develop a mathematical model for a given gas separation and to use gPROMS language as a tool to numerically solve this problem.

The main objective of this project is to learn how to model adsorption processes in general so there is plenty of flexibility in selecting the separation to be targeted.

About the Researcher

Carlos Grande

Associate Professor, Chemical Engineering

Affiliations

Education Profile

- PhD, Chemical Engineering, Faculty of Engineering University of Porto, Portugal Diploma of Chemical Engineering (5 years degree), South University, Argentina

Research Interests

a€‹Prof. Grande's research interests cover all aspects of adsorption processes, from the characterization, scale-up and formulation of new adsorbent materials to the process design, simulation and testing.A Prof. Grande's research also covers process intensification routes that digitalization can bring to industrial manufacturing. In particular, the effects and novel pathways that can be achieved by using novel architectures of equipment and internals.Selected Publications

- ""Multi-purpose structured catalysts designed and manufactured by 3D printing"", Lind, A.; Vistad, A˜.; Sunding, M. F.; Andreassen, K. A.; Cavka, J. H.; Grande, C. A. Materials & design, 2020, 187, 108377.

- ""Shaping of metal-organic framework UiO-66 using alginates: effect of operation variables"", Lee, D. W.; Didriksen, T.; Olsbye, U.; Blom, R.; Grande, C. A. Sep. Purif. Technol., 2020., 235, 116182

- ""Evaluation of simplified pressure swing adsorption cycles for bio-methane production"", Canevesi, R. L. S.; Andreassen, K. A.; Da Silva, E. A.; Borba, C. E.; Grande, C. A. Adsorption, 2019, 25, 783-793

- ""Life-cycle assessment as a tool for eco-design of metal-organic frameworks (MOFs)"", Grande, C. A.; Blom, R.; Spjelkavik, A.; Moreau, V.; Payet, J. Sust. Mater. Tech., 2017, 14, 11-18.

- ""Multi-bed Vacuum Pressure Swing Adsorption for Carbon Dioxide Capture from Flue Gases"", Liu, Z.; Grande, C. A.; Li, P.; Yu, J.; Rodrigues, A. E. Sep. Purif. Technol., 2011, 81, 307-317.

Desired Project Deliverables

Learn to use gPROMS software and how to transform equation-based problems into computer code.

Understand the important variables that are important for simulation and optimization of adsorption processes.

Participate in a joint scientific publication.

We are shaping the

World of Research

Be part of the journey with VSRP

3-6 months

Internship period

100+

Research Projects

3.5/4

Cumulative GPA

310

Interns a Year