Project Details

Program

Chemical Engineering

Field of Study

reaction engineering ; transport phenomena ; digitalization

Division

Physical Sciences and Engineering

Faculty Lab Link

Center Affiliation

Advanced Membranes and Porous Materials Center

Project Description

High-added value chemicals and active pharmaceutical ingredients (APIs) are normally produced using batch technology. Some of those chemical compounds can be produced in continuous flow reactors (i.e. continuous manufacturing).

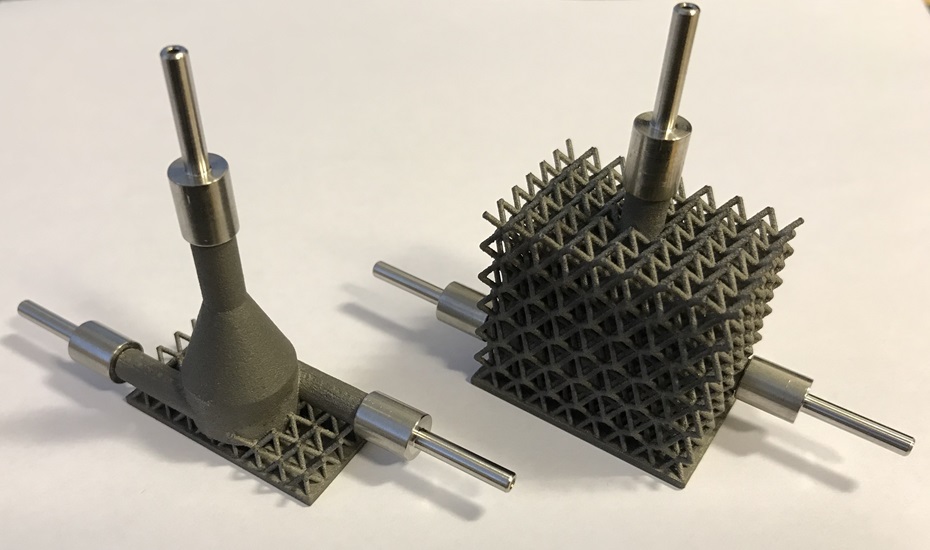

Advanced techniques of manufacturing like 3D printing allow us to produce specific reactors that are optimized to produce a certain chemical or pharmaceutical component. Such novel designs are of importance when heat of reaction needs to be evacuated faster or when improved mixing is required, etc.

The current project aims to use digital tools to produce custom designs of continuous flow reactors. The student will also be involved in the production of the reactor and on its flow pattern characterization (determination of residence time distribution).

About the Researcher

Carlos Grande

Associate Professor, Chemical Engineering

Affiliations

Education Profile

- PhD, Chemical Engineering, Faculty of Engineering University of Porto, Portugal Diploma of Chemical Engineering (5 years degree), South University, Argentina

Research Interests

a€‹Prof. Grande's research interests cover all aspects of adsorption processes, from the characterization, scale-up and formulation of new adsorbent materials to the process design, simulation and testing.A Prof. Grande's research also covers process intensification routes that digitalization can bring to industrial manufacturing. In particular, the effects and novel pathways that can be achieved by using novel architectures of equipment and internals.Selected Publications

- ""Multi-purpose structured catalysts designed and manufactured by 3D printing"", Lind, A.; Vistad, A˜.; Sunding, M. F.; Andreassen, K. A.; Cavka, J. H.; Grande, C. A. Materials & design, 2020, 187, 108377.

- ""Shaping of metal-organic framework UiO-66 using alginates: effect of operation variables"", Lee, D. W.; Didriksen, T.; Olsbye, U.; Blom, R.; Grande, C. A. Sep. Purif. Technol., 2020., 235, 116182

- ""Evaluation of simplified pressure swing adsorption cycles for bio-methane production"", Canevesi, R. L. S.; Andreassen, K. A.; Da Silva, E. A.; Borba, C. E.; Grande, C. A. Adsorption, 2019, 25, 783-793

- ""Life-cycle assessment as a tool for eco-design of metal-organic frameworks (MOFs)"", Grande, C. A.; Blom, R.; Spjelkavik, A.; Moreau, V.; Payet, J. Sust. Mater. Tech., 2017, 14, 11-18.

- ""Multi-bed Vacuum Pressure Swing Adsorption for Carbon Dioxide Capture from Flue Gases"", Liu, Z.; Grande, C. A.; Li, P.; Yu, J.; Rodrigues, A. E. Sep. Purif. Technol., 2011, 81, 307-317.

Desired Project Deliverables

Learn how to produce novel designs and transform them into high quality meshes for 3D printing. Rhino3D and Grasshopper will be used for parametric geometry design.

Categorize the advantages, but also the limitations of 3D printing as a manufacturing tool for chemical reactors.

Understand residence time distribution concepts and participate in a joint scientific publication.